What are the quality standards for Calcium Formate Acce?

Jul 01, 2025

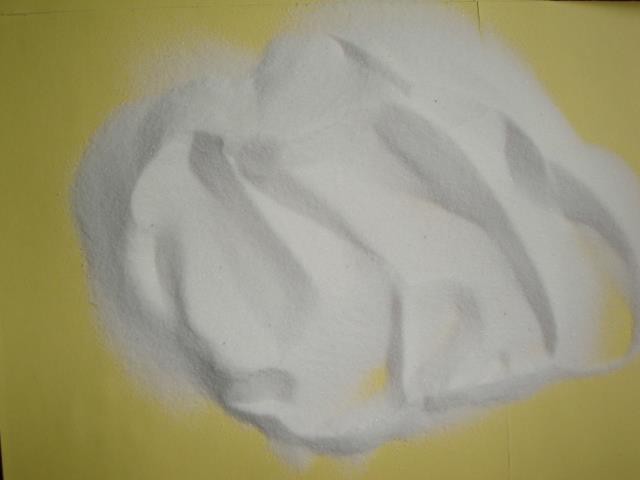

Calcium formate, a versatile chemical compound, has found wide - ranging applications in various industries. As a leading supplier of Calcium Formate Acce, I understand the significance of quality standards in this field. In this blog, I will delve into the key quality standards for Calcium Formate Acce and explain why they matter.

Chemical Purity

One of the most fundamental quality standards for Calcium Formate Acce is its chemical purity. High - purity calcium formate is crucial for its performance in different applications. In general, the purity of calcium formate should be at least 98%. Impurities can have a negative impact on the effectiveness of calcium formate. For example, in the feed industry, impurities may contain harmful substances that can be detrimental to the health of livestock. When used as a cement accelerator, impurities can affect the setting time and strength development of the cement.

Our company ensures that the Calcium Formate Acce we supply meets the highest purity standards. Through advanced purification processes, we are able to remove most of the impurities, providing our customers with a product that performs consistently. The Calcium Formate Cafo Feed Grade we offer is carefully refined to ensure it is safe and effective for animal consumption.

Particle Size

Particle size is another important quality parameter for Calcium Formate Acce. The particle size can influence the solubility and reactivity of calcium formate. In the cement industry, a suitable particle size distribution is necessary for the uniform dispersion of calcium formate in the cement mixture. A fine particle size can increase the surface area of calcium formate, allowing it to react more quickly with other components in the cement, thus accelerating the setting process.

For feed applications, the particle size also matters. Smaller particles are more easily digested by animals, improving the bioavailability of calcium formate. Our production process is designed to control the particle size of Calcium Formate Acce precisely. We can customize the particle size according to the specific requirements of our customers, whether they need a product for cement or feed use.

Moisture Content

Moisture content is a critical factor that affects the stability and storage of Calcium Formate Acce. High moisture content can lead to caking, which makes the product difficult to handle and can also reduce its quality over time. Excessive moisture can also promote the growth of microorganisms, especially in feed - grade calcium formate.

We have strict control measures in place to ensure the moisture content of our Calcium Formate Acce is within the acceptable range. Typically, the moisture content should be less than 0.5%. By maintaining low moisture content, we can guarantee the long - term stability of our product and ensure that it remains in good condition during storage and transportation.

Heavy Metal Content

Heavy metal content is a major concern, especially for products used in the food and feed industries. Heavy metals such as lead, mercury, cadmium, and arsenic can be toxic to humans and animals even at low concentrations. Therefore, the content of heavy metals in Calcium Formate Acce must be strictly controlled.

Our company adheres to international standards for heavy metal limits. We conduct regular testing to ensure that the heavy metal content in our Calcium Formate Acce is well below the allowable levels. This commitment to safety and quality makes our Calcium Diformate a reliable choice for customers in the feed industry.

pH Value

The pH value of Calcium Formate Acce can affect its chemical properties and performance. In some applications, such as in the production of certain chemical products, a specific pH range is required for the reaction to proceed smoothly. In the cement industry, the pH value of calcium formate can influence its interaction with other additives and the overall performance of the cement.

We carefully monitor and adjust the pH value of our Calcium Formate Acce during the production process. By maintaining a stable pH value, we can ensure that the product performs as expected in different applications.

Applications and Quality Requirements

Cement Industry

In the cement industry, Calcium Formate Acce is used as an accelerator. The quality requirements in this application are mainly focused on its ability to accelerate the setting time and enhance the early strength of cement. A high - purity calcium formate with a suitable particle size and low moisture content is essential. Our Calcium Formate As Cement Accelerator is specifically formulated to meet these requirements. It can significantly reduce the setting time of cement, especially in cold weather conditions, and improve the early strength development, which is crucial for construction projects.

Feed Industry

For the feed industry, the safety and nutritional value of Calcium Formate Acce are of utmost importance. The product must be free from harmful substances and have a high bioavailability. The low heavy metal content and proper particle size ensure that it is safe and easily digestible for animals. Our Calcium Formate Cafo Feed Grade provides a good source of calcium and formic acid for livestock, which can improve their growth performance and health.

Why Choose Our Calcium Formate Acce

As a supplier, we are committed to providing high - quality Calcium Formate Acce that meets or exceeds industry standards. Our state - of - the - art production facilities and strict quality control systems ensure that every batch of our product is consistent in quality. We also offer excellent customer service, providing technical support and customized solutions to meet the specific needs of our customers.

If you are looking for a reliable supplier of Calcium Formate Acce, we would be delighted to discuss your requirements. Whether you need a product for the cement industry or the feed industry, we have the expertise and resources to provide you with the best solution. Contact us today to start a discussion about your procurement needs.

References

- ASTM International. Standards related to chemical purity and particle size for industrial chemicals.

- European Food Safety Authority. Guidelines on heavy metal limits in feed additives.

- American Concrete Institute. Research on the use of accelerators in cement.